2. We can increase the air humidity in the workplace and the living room to reduce the generation of static electricity;

3. It is to add a grounding wire to the machine equipment to timely introduce static electricity into the earth;

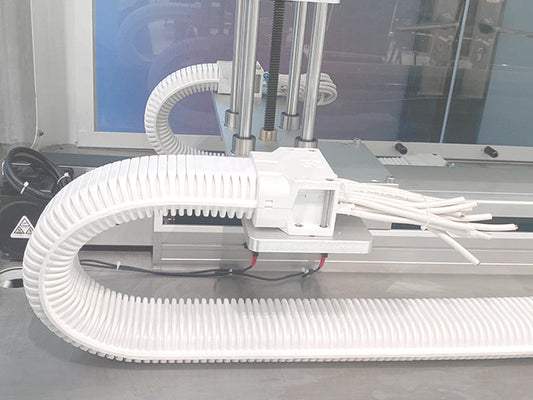

The plastic towline looks like a tank chain, and it is composed of many unit links. The links can rotate freely. The inner height, outer height and pitch of the same series of plastic towlines are the same, and the inner width and bending radius R of the towline can be different. Selection, the unit chain link is composed of left and right chain plates and upper and lower cover plates. Each section of the drag chain can be opened, which is convenient for assembly and disassembly without threading. After opening the cover plate, cables, oil pipes, air pipes, water pipes, etc. can be put into the drag chain. Separators can also be provided to separate the space in the chain as needed.