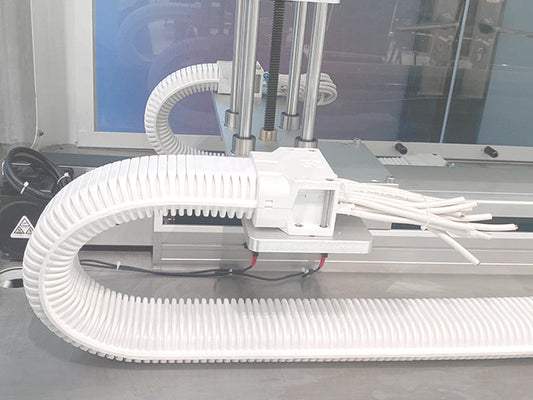

Plastic drag chains, nylon drag chain, plastic cable carrier are common components in automation equipment, mainly playing a role in cable duct protection and traction. So, what are the main factors for selecting plastic drag chains and what are the basic parameters of plastic drag chains? Below, the editor of Guangrou Dust Free Drag Chain will briefly introduce the basic parameters of plastic drag chains:

(1) Material: Plastic drag chains require the use of reinforced nylon, and drag chains produced using engineering plastics can have high pressure and tensile loads, good toughness, high elasticity, and wear resistance, flame retardant, stable performance at high and low temperatures, and can be used outdoors.

(2) Resistance: Plastic drag chains typically require oil and salt resistance, as well as certain acid and alkali resistance.

(3) Operating speed and acceleration: The specific speed and acceleration of plastic drag chains depend on the operating environment.

(4) Operating life: Plastic pad iron is divided into bridge type drag chains and fully enclosed drag chains according to its structure, and is divided into original packaging plastic and recycled plastic according to its raw materials; The content of nylon determines the strength and wear resistance of the drag chain, as well as the noise level during operation. The nylon content of plastic drag chains ranges from 5% to 17%, but exceeds 19%.

(5) Selection of plastic drag chains: The model of plastic drag chains is mainly determined by the internal height and width, and can also be customized according to the external height and width.

The above is an introduction to the basic parameters of plastic drag chains. To learn more about drag chains, please keep an eye on the official website of Guangrou Dust Free Drag Chain.