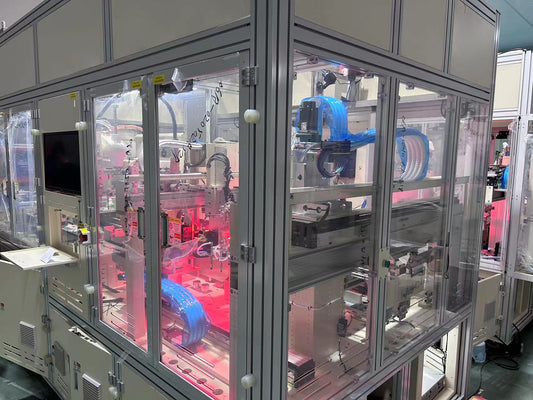

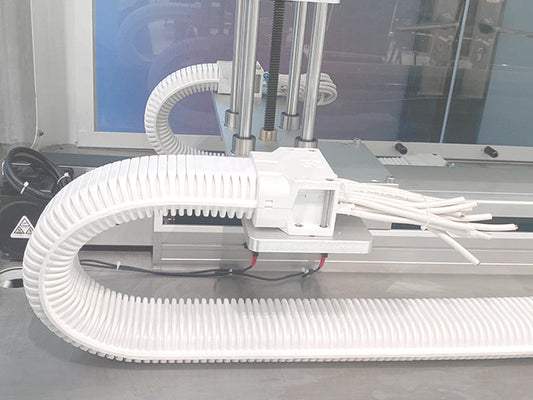

Heavy duty dust-free drag chains and dust-free drag chains are both crucial components used in cleanroom environments to ensure the smooth and safe operation of machinery and equipment. While they share the common goal of guiding and protecting cables and hoses, there are notable differences between the two types of drag chains.

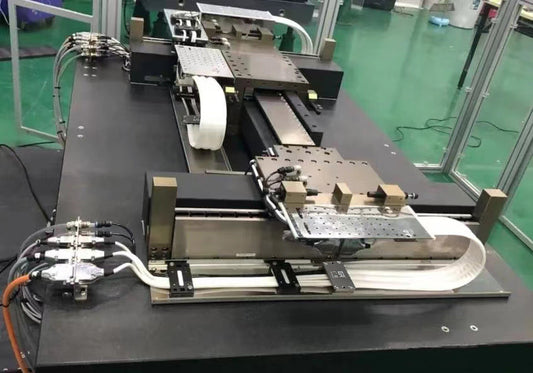

Heavy duty dust-free drag chains are designed for applications that involve heavy machinery or equipment that exerts high levels of force on the drag chain. These drag chains are built with reinforced materials and robust construction to withstand the increased stress and strain. They are ideal for use in industrial settings or environments with rugged conditions where durability and strength are essential.

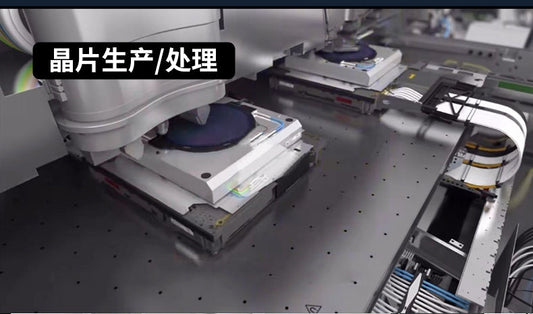

On the other hand, standard dust-free drag chains are more commonly used in cleanroom environments where the machinery and equipment are lighter and do not require as much resistance to force. These drag chains are made from high-quality materials to ensure cleanliness and precision in the controlled environment of the cleanroom. They offer smooth and efficient cable and hose guidance while maintaining a dust-free environment.

In summary, the main differences between heavy duty dust-free drag chains and dust-free drag chains lie in their construction, durability, and application. Selecting the right drag chain for a specific cleanroom environment depends on the type of machinery and equipment being used, as well as the level of force exerted on the drag chain. Understanding these differences is crucial in ensuring the optimal performance and longevity of the drag chains in cleanroom applications.