What are the application scenarios for dust-free drag chains? Why use dust-free drag chains?

The application scenarios of dust-free drag chains mainly involve industries such as semiconductor manufacturing, precision machinery, medical equipment, food processing, and chemical engineering. In these industries, the role of dust-free drag chains is very important. Now, let me introduce the applications and their reasons in these scenarios for you.

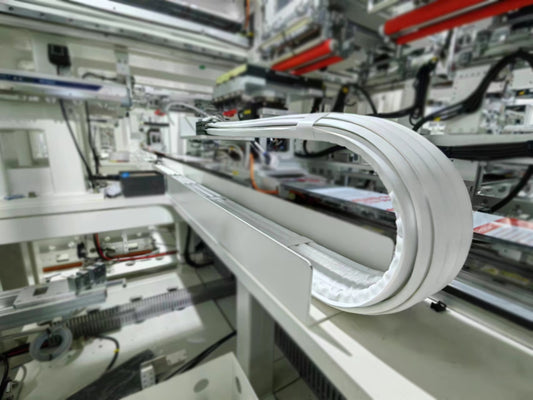

Firstly, in semiconductor manufacturing, dust-free drag chains are widely used. Semiconductor manufacturing requires strict control of dust and impurities, as they may cause product defects or damage. Dust free drag chains can provide seamless connections, avoiding the invasion of dust and impurities. At the same time, their materials and design can prevent friction and static electricity accumulation, thereby ensuring the cleanliness of the production environment and product quality.

Secondly, in the precision machinery industry, dust-free drag chains also play a crucial role. The industry requires precision and high stability, and drag chains can provide smooth sliding and the ability to protect cables and pipelines. Especially in some large mechanical equipment, dust-free drag chains can avoid the dust and pollution brought by traditional cable drag chains, ensuring the cleanliness of the production environment and the accuracy of the machine.

In addition, the use of dust-free drag chains is also necessary in medical equipment. Medical equipment requires strict control of dust and bacteria to ensure the health and safety of patients. A dust-free drag chain can provide a dust-free environment, while its smooth surface and sealed design can prevent the invasion of bacteria and viruses, ensuring the cleanliness and safety of the equipment.

In the food processing industry, dust-free drag chains can ensure the cleanliness and hygiene of the production environment. Food processing requires the control of microorganisms and impurities, and dust-free drag chains can avoid dust and pollution caused by traditional cable drag chains. At the same time, their materials and design can prevent the invasion of bacteria and viruses, ensuring the safety and hygiene of food.

Finally, in the chemical industry, dust-free drag chains can provide higher safety and reliability. The chemical industry needs to control ignition sources and static electricity accumulation, and the materials and design of dust-free drag chains can avoid friction and static electricity accumulation. At the same time, their sealed design can prevent the infiltration and leakage of chemical liquids, ensuring production safety and reliability.

In summary, the application scenarios of dust-free drag chains are very extensive and play an important role in different industries.