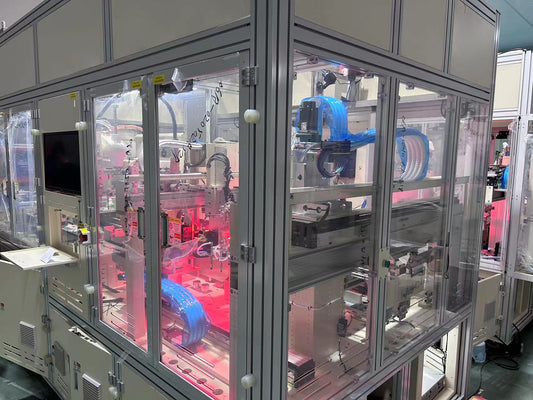

In high-precision industries such as semiconductor manufacturing, biotechnology, and pharmaceuticals, maintaining a contaminant-free environment is critical. A cleanroom cable chain (also known as a cleanroom drag chain or dust-free cable carrier) is engineered to meet these stringent demands. Designed for automation equipment in sterile environments, this advanced component ensures seamless cable management while preventing dust generation and electrostatic interference. Below, we explore its features, applications, and advantages.

What Is a Cleanroom Cable Chain?

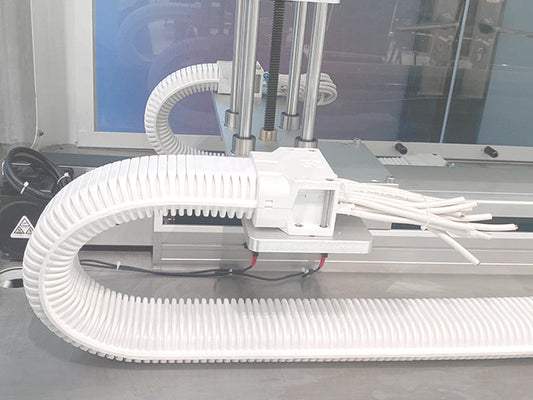

A cleanroom cable chain is a specialized drag chain system tailored for ultra-clean environments. Unlike traditional cable carriers, it incorporates closed-loop designs, anti-static materials, and low-particulate construction to minimize contamination risks. Its primary function is to protect and guide cables, hoses, and pipelines in automated machinery while adhering to strict cleanliness standards like ISO Class 100 or 1,000.

Key Features of Cleanroom Cable Chains

-

Dust-Free & Contaminant-Resistant Design

-

Sealed Structure: Fully enclosed compartments block dust ingress, ensuring compliance with cleanroom protocols.

-

Anti-Static Materials: Made from polymers like modified PA (polyamide) or e-PTFE (expanded polytetrafluoroethylene), these chains prevent static buildup, safeguarding sensitive electronics.

-

-

High Durability & Flexibility

-

Withstands 30+ million bending cycles (50mm radius) and extreme mechanical stress, ideal for high-speed automation.

-

Modular designs allow easy customization for varying cable diameters and complex motion paths.

-

-

Easy Maintenance & Hygiene

-

Smooth surfaces and detachable components simplify cleaning, reducing downtime in sterile environments like medical labs or food processing plants.

-

-

Low Noise & Lightweight Construction

-

Optimized for quiet operation (<60 dB), critical in noise-sensitive settings such as research facilities.

-

Applications Across Industries

-

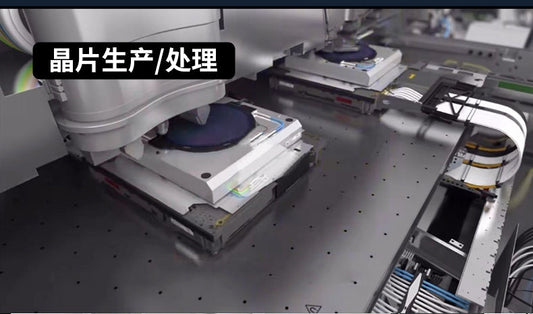

Semiconductor & Electronics Manufacturing

-

Protects wiring in lithography and etching machines, preventing particle-induced defects in microchips.

-

-

Medical & Pharmaceutical Equipment

-

Resists chemical corrosion and bacterial growth, ensuring compliance with FDA and GMP standards.

-

-

Food & Beverage Processing

-

Food-grade materials eliminate contamination risks, while corrosion-resistant designs endure washdowns and acidic environments57.

-

-

Automotive & Robotics

-

Supports high-speed robotic arms and assembly lines with reliable cable management.

-

Why Choose a Cleanroom Cable Chain?

-

Enhanced Product Quality: By eliminating dust and static, it reduces defects in precision manufacturing.

-

Cost Efficiency: Long service life (up to 12 million cycles) lowers replacement frequency and maintenance costs.

-

Regulatory Compliance: Meets ISO 9001, ISO 14001, and TUV certifications for quality and safety.

Conclusion

A cleanroom cable chain is indispensable for industries where contamination control and operational reliability are non-negotiable. Its innovative design, durability, and adaptability make it the backbone of modern automation systems in sterile environments. For tailored solutions, explore GRPODCN’s range of certified cleanroom cable chains, engineered to elevate your production efficiency while safeguarding your cleanroom integrity.