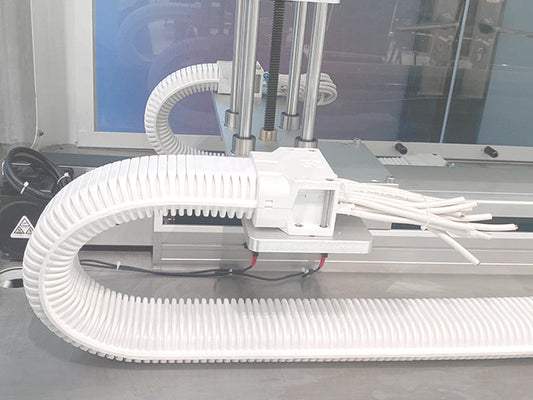

In industries where cleanliness is paramount, such as pharmaceuticals, biotechnology, and semiconductor manufacturing, the dust free drag chain plays a crucial role in maintaining a controlled environment. This type of cable drag chain is specifically engineered to meet the stringent requirements of cleanroom settings, where even the smallest particles can compromise product integrity and safety.

Key Features of Dust Free Drag Chains

1. Anti-Static Properties

One of the standout features of the dust free drag chain is its anti-static design. In cleanrooms, static electricity can attract dust and other contaminants, which poses a significant risk. The materials used in these cable drag chains are formulated to dissipate static, thereby minimizing the potential for contamination and ensuring that sensitive equipment operates efficiently.

2. Friction Resistance

Friction can lead to wear and tear on traditional cable carriers, resulting in downtime for maintenance and repairs. Dust free drag chains are designed to be highly friction-resistant, allowing for smooth movement of cables and extending the life of both the drag chain and the cables it carries. This durability is essential in environments where reliability is critical.

3. High Flexibility

Flexibility is another key characteristic of these cleanroom cable carriers. They are designed to accommodate various cable types and configurations, enabling seamless integration into complex automation systems. This flexibility ensures that the cables remain untangled and organized, even in the most dynamic environments.

Applications of Dust Free Drag Chains

Dust free drag chains are widely used in various applications within cleanroom environments. Here are a few notable ones:

-

Pharmaceutical Manufacturing: In the production of medications, maintaining a dust-free environment is essential to prevent contamination during the manufacturing process.

-

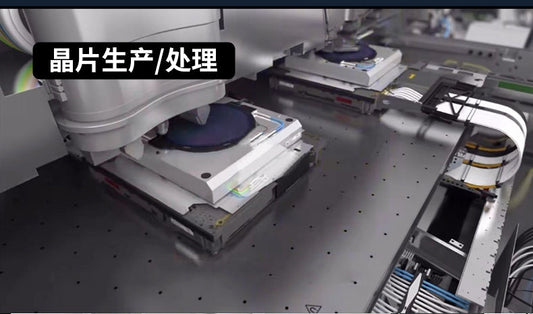

Semiconductor Production: The semiconductor industry requires ultra-clean conditions to produce chips. Dust free drag chains help manage the large volume of cables used in the machinery, without contributing to airborne particles.

-

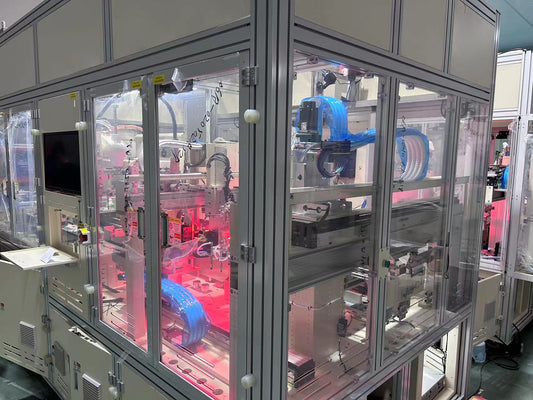

Robotics and Automation: As automation becomes more prevalent in cleanrooms, these cable drag chains facilitate the smooth and efficient operation of robotic systems, keeping essential connections tidy and functional.

-

Laboratories: In research and development labs, where experiments can be sensitive to environmental changes, dust free drag chains ensure that equipment remains operational and free from contaminants.

In conclusion, the dust free drag chain is an indispensable component of modern cleanroom automation equipment. With its anti-static properties, friction resistance, and high flexibility, it meets the rigorous demands of various industries, ensuring that operations remain efficient and contamination-free. For anyone involved in cleanroom design or automation, incorporating cleanroom cable carriers like dust free drag chains is a proactive approach to maintaining industry standards and safeguarding product quality.