In industries where precision and cleanliness are non-negotiable, such as pharmaceuticals, semiconductor manufacturing, and biotechnology, maintaining a contamination-free environment is critical. Cleanroom cable carriers and cleanroom drag chains are specialized components designed to meet the stringent demands of these controlled environments. This article explores their unique features, applications, and benefits in ensuring operational efficiency while adhering to cleanroom standards.

What Are Cleanroom Cable Carriers and Drag Chains?

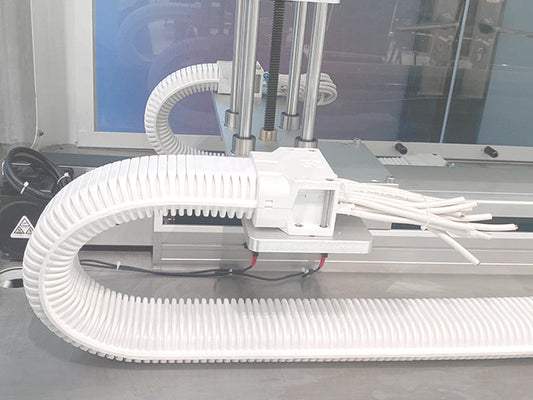

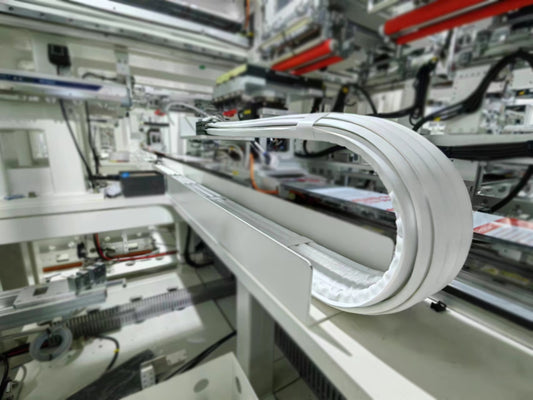

Cleanroom cable carriers (also known as cleanroom drag chains, Dust-free drag chains) are engineered to manage and protect cables, hoses, and tubing in environments where even microscopic particles can disrupt processes. Unlike standard cable carriers, these systems are constructed with materials and designs that minimize particulate generation, static electricity, and chemical emissions—key requirements for ISO-classified cleanrooms.

Key Features of Cleanroom Drag Chains

1. Low-Particulate Materials: Made from anti-static polymers or stainless steel, cleanroom drag chains prevent dust and debris shedding.

2. Sealed Design: Enhanced sealing mechanisms block internal lubricants or external contaminants from escaping into the environment.

3. Smooth Surfaces: Rounded edges and polished surfaces reduce friction and particle accumulation.

4. Chemical Resistance: Resistant to disinfectants and solvents used in cleanroom sanitation protocols.

Applications in Cleanroom Environments

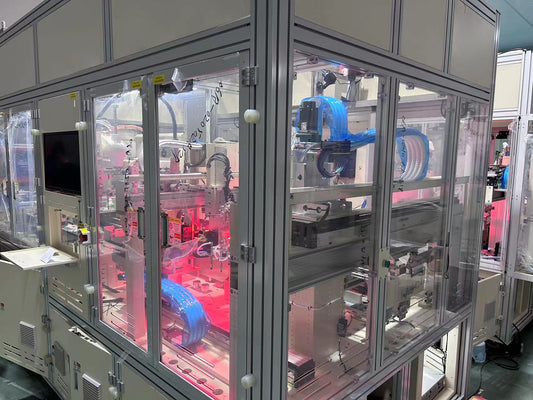

Cleanroom cable carriers are indispensable in sectors such as:

- Pharmaceutical Production: Safeguarding wiring in automated pill-packaging systems.

- Electronics Manufacturing: Protecting sensitive circuits during robotic assembly processes.

- Medical Device Fabrication: Ensuring sterile conditions for equipment handling implantable devices.

Their ability to operate silently and reliably under strict hygiene protocols makes them ideal for repetitive, high-precision tasks.

Benefits of Using Cleanroom Cable Carriers

1. Contamination Control: By eliminating particulate release, they help maintain ISO 14644-1 cleanliness standards.

2. Extended Equipment Lifespan: Reduced wear on cables and hoses lowers maintenance costs.

3. Compliance: Meet regulatory requirements for industries like FDA-regulated biotech labs.

4. Energy Efficiency: Low-friction designs minimize power consumption in automated systems.

Choosing the Right Cleanroom Drag Chain

When selecting a cleanroom cable carrier, consider:

- ISO Class Requirements: Match the carrier’s particulate emission rating to your cleanroom level.

- Load Capacity: Ensure it supports the weight and movement range of your cables.

- Chemical Compatibility: Verify resistance to cleaning agents used in your facility.

Leading manufacturers often provide custom solutions tailored to specific cleanroom applications.

Cleanroom cable carriers and drag chains are unsung heroes in contamination-sensitive industries. Their specialized design not only protects critical wiring but also upholds the integrity of sterile environments. By investing in high-quality cleanroom drag chains, manufacturers can achieve seamless operations, regulatory compliance, and long-term cost savings. As automation advances in sectors like nanotechnology and aerospace, the demand for these precision components will only grow—solidifying their role as a cornerstone of cleanroom technology.