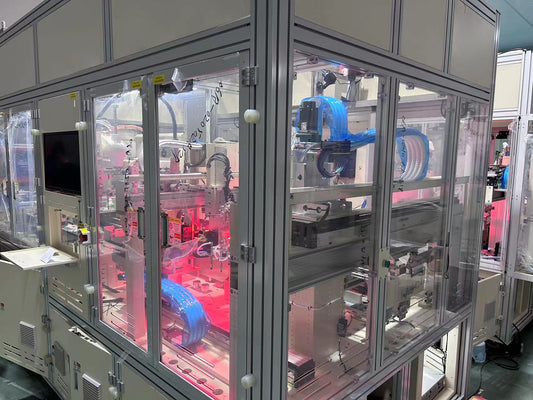

In industries such as pharmaceuticals, aerospace, and electronics, maintaining a dust-free environment is critical. One of the key components in cleanroom applications is the cleanroom cable drag chain. These specialized chains play a vital role in safeguarding sensitive equipment and ensuring operational efficiency.

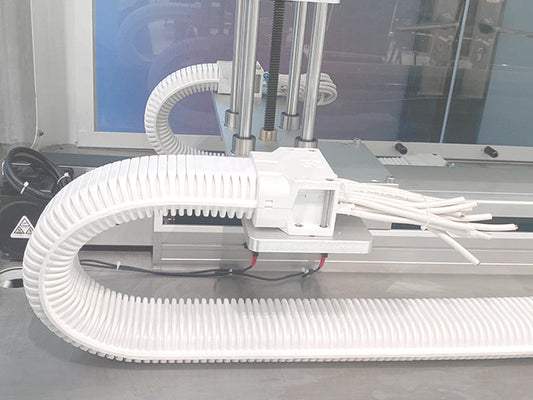

A cleanroom cable drag chain is designed to protect cables and hoses from wear and tear while allowing for smooth movement along defined paths. Unlike traditional drag chains, cleanroom variations are engineered to meet stringent cleanliness standards. They are made from materials that minimize particle shedding and are often used in environments where contamination can have serious consequences.

The use of a dust-free drag chain further enhances cleanroom conditions. These chains are constructed to trap and contain contaminants, preventing them from spreading throughout the workspace. By utilizing dust-free technology, facilities can maintain lower particulate levels, thereby improving air quality and compliance with industry regulations.

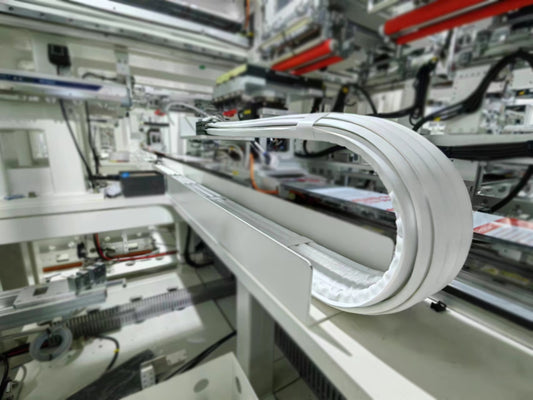

Another important type is the corrugated tube drag chain, which offers flexibility and protection for cables in dynamic applications. Its design allows for the efficient routing of cables while minimizing the risk of damage. Corrugated tubes are particularly beneficial in cleanroom environments, as they provide an added layer of dust protection, further reducing the risk of contamination.

Implementing these drag chains not only improves the longevity of cables but also reinforces a cleanroom’s integrity. Facilities utilizing cleanroom cable drag chains and related technologies can experience fewer equipment failures and reduced maintenance costs, ultimately leading to enhanced productivity.

In conclusion, investing in a cleanroom cable drag chain, dust-free drag chain, or corrugated tube drag chain is essential for maintaining the high standards required in cleanroom environments. By minimizing the risk of contamination, these solutions contribute to the overall efficiency and safety of critical operations.