The working principle of flexible and dust-free corrugated tube drag chains mainly involves protective and guiding functions, making them suitable for industrial applications that require clean environments, such as electronics, pharmaceuticals, and food industries.

The fundamental working principles can be summarized as follows:

-

Structural Composition:

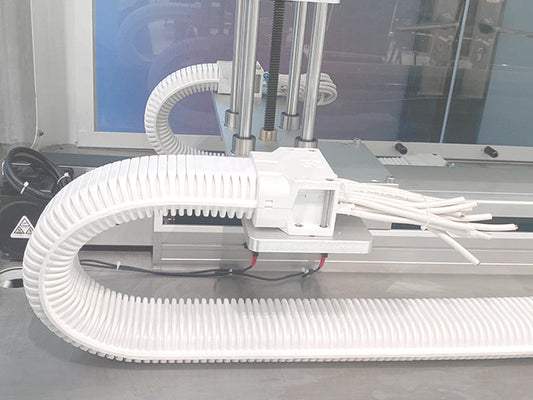

- Flexible and dust-free corrugated tube drag chains typically consist of corrugated tubes, chain bodies, brackets, and connectors. The design of the corrugated tubes allows for both flexibility and sufficient strength.

-

Protection of Cables and Pipes:

- The interior of the drag chain can accommodate multiple cables and hoses. The closed design of the corrugated tubes prevents dust, dirt, and other contaminants from entering, ensuring the safety of the internal cables and pipes.

-

Flexibility and Dynamic Movement:

- As the equipment operates, the drag chain moves in conjunction with the device, adapting to different positions and states. The wave structure of the corrugated tubes provides excellent flexibility, allowing the drag chain to bend and stretch without causing pressure or damage to the internal cables and pipes.

-

Vibration Damping and Noise Isolation:

- The design of the corrugated tubes also helps reduce vibrations and noise generated by the motion of the equipment, providing a quieter working environment for operators.

-

Installation and Maintenance:

- Flexible and dust-free corrugated tube drag chains are typically designed for easy installation and replacement. During maintenance, it is sufficient to open the corrugated tubes for convenient internal inspection and cable replacement, reducing maintenance complexity.

-

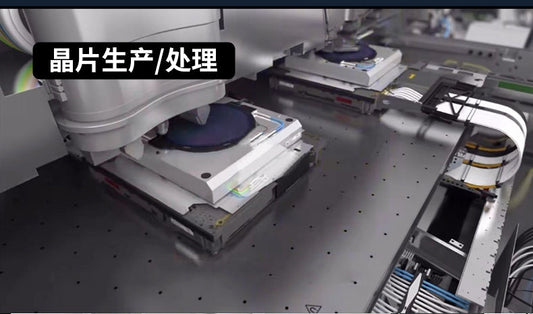

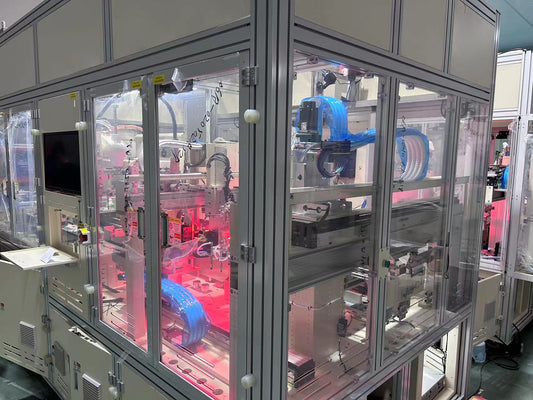

Application Range:

- Due to their superior performance, flexible and dust-free corrugated tube drag chains are widely used in various scenarios that require flexible movement and dust protection, including automated production lines, robotics, printers, and CNC machine tools.

In summary, the flexible and dust-free corrugated tube drag chain ensures safe operation in various professional environments by providing effective protection, flexible guidance, and efficient installation and maintenance processes. If you would like to know more specific technical details or application examples, please let me know!